National Grid completes record-breaking pour of cement-free concrete

Posted: Friday, May 12th, 2023

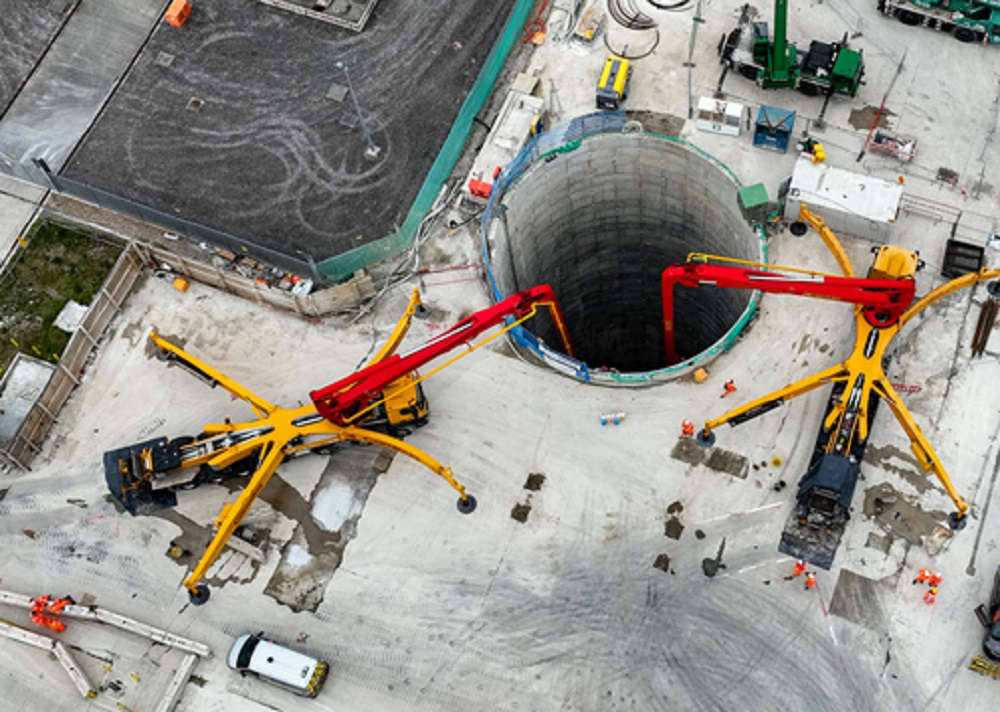

National Grid and its contractor Hochtief-Murphy Joint Venture (HMJV) completed the world’s largest ever continuous pour of Earth Friendly Concrete at London Power Tunnels, a £1bn project to rewire London. 736 m3, or 736,000 litres (enough to fill around two 25m swimming pools) of more sustainable, cement-free concrete was poured to fill the base of the 55m deep tunnel drive shaft at National Grid’s Hurst Substation in South London. The cement-free solution was developed by Wagners and supplied by Capital Concrete and uses a binder of ground granulated blast furnace slag and fly ash geopolymer concrete system chemically activated using industrial waste products instead of cement. The concrete reduces carbon by around 64% saving an estimated 111kg of CO2 per cubic metre poured in comparison to concrete which would have traditionally been used. The use of Earth Friendly Concrete was driven forward by a team of young engineers on the project and supported by HMJV’s engineering experts and AECOM, Mott MacDonald and WSP, following several trials at different London Power Tunnels sites. The record-breaking pour on Earth Day (22 April) at National Grid’s Hurst substation site was needed to infill the base of the 55m deep tunnel shaft to its permanent level, following the successful completion of 9.2km of tunnelling over 2 tunnel drives from Hurst to Eltham and Crayford. Elsewhere on the London Power Tunnels project, there are several measures in place to reduce the environmental impact of construction and keep National Grid on track to achieve net zero carbon construction by 2025/26. These include: Optimisation of designs and construction methodologies of the tunnel and shaft network by HMJV saving approximately 50,000 tonnes of CO2, leading to a 30% reduction against baseline. 99.98% of project waste being diverted away from landfill, a 21% reduction against the carbon reduction pre-project baseline for shafts, tunnels and headhouses, equivalent to 25,250 tonnes of CO2. A new 400kV substation at the heart of the project in Bengeworth Road, Lambeth will be built using SF6 free gas-insulated switchgear technology in a UK first. This world record-breaking pour also offers the opportunity to evaluate the technology ahead of future possible rollout across our network in England and Wales, demonstrating our ambition to achieve net zero construction across all our projects by 2025/26 Raj Kundan, technical lead for Hochtief-Murphy Joint Venture said: “Completing the largest ever continuous cement-free concrete pour is a testament to the ingenuity and collaboration of all involved working as part of this Project 13 Enterprise scheme, and shows how a client, contractor and the supply chain can work together to help take a major step moving the industry forward in reducing carbon emissions.”

Trending Stories

-

Essex electrician has roundabout signs rejected

Essex electrician has roundabout signs rejected

A sparkie’s bid to sponsor signs on two roundabouts has been refused by planning chiefs who described them as “clutter”

-

Barbie caused a ‘worldwide’ shortage of pink paint

Barbie caused a ‘worldwide’ shortage of pink paint

Barbie needed so much fluorescent pink paint that it caused a worldwide supply shortage for an entire company

-

Builders find body of man murdered in the 1960s and buried in back garden

Builders find body of man murdered in the 1960s and buried in back garden

A woman who bought a South London house was left horrified after builders discovered the body of a man murdered in the 1960s and buried in her garden 14 months after she moved in

-

'Government insulation scheme ruined my home'

'Government insulation scheme ruined my home'

A home-owner said his flat has been ruined by black mould caused by a government "green" insulation schem

-

Builder celebrates lottery win by buying his coworkers bacon butties

Builder celebrates lottery win by buying his coworkers bacon butties

A builder from Milford Haven who won big on the lottery celebrated his victory by treating all his workmates to a round of bacon rolls

Comments

Add a comment